Russwood Battening System

Russwood Battening System offers an environmentally friendly, engineer-assessed, method of fixing timber cladding. It is easy to install and dismantle at end of life, supporting the circular economy of materials. It is also compatible with Securo Firebreather™ Cavity Barriers for enhanced fire resistance. Purposefully designed to support architects with external cladding detailing, Russwood Battening System simplifies and speeds up installation as well as reducing on-site wastage for contractors.

Russwood Battening System has been independently assessed to be compliant with EN 1995-1-1: Eurocode 5: Design of timber structures in advance of any other comparable cladding batten support system on the market. The system comprises of Thermopine® cladding battens, load-bearing screw fixings and Kompefix® ventilation strips from our Austrian fixings partner Sihga, plus Securo Firebreather™ Cavity Barriers.

Thermopine® cladding battens

Thermopine® is a thermally treated timber with enhanced stability and durability. Thermopine® is durable through its full cross section due to the thermal treatment process, meaning that any pieces cut, machined or reworked during installation do not expose any vulnerable unmodified material.

In contrast, preservative impregnated softwood timber battens only have a protective envelope, which is compromised when it is cut. Building codes state that any cuts should be touched up with a preservative but this consumes time and labour, or in some cases is not carried out at all, which can lead to unprotected parts developing rot, potentially leading to structural problems.

Thermopine® cladding battens contain no hazardous chemicals, unlike standard preservative treated timbers which can be hazardous if disposed of incorrectly. Russwood’s system also offers the benefit that it can be disassembled and reused, recycled or remanufactured the at end of the building’s life making it a highly sustainable product.

Our in-house team of technicians have carefully selected three batten shapes in order to make the system compatible with vertical, horizontal and diagonal cladding arrangements.

- RWB001 – 42x42mm square-edge* batten

- RWB002 – 45x20mm square-edge* counter batten

- RWB003 – 46x42mm sloped* horizontal batten

*battens will have rounded corners

The three batten shapes follow an engineer’s calculations to make the system compliant with EN 1995-1-1: Eurocode 5: Design of timber structures, ensuring sufficient fixing embedment and structural integrity for fixing external timber cladding in the harshest UK conditions. Please contact our team of technicians for an advice on how to specify a suitable battening arrangement for your cladding design.

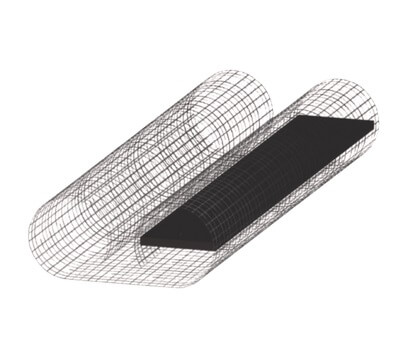

The batten shapes contain machined-in grooves for easy and accurate fixing using GoFix® MS II screws and KompeFix® flexible ventilation strips.

GoFix® MS II screws

Russwood Battening System is supplied with load bearing GoFix® MS II screws with SC7 corrosion resistant coating from our Austrian fixings engineer and manufacturing partner Sihga. The GoFix® MS II screws for load-bearing connections have been carefully selected and independently assessed by a structural engineer to make their specification compliant with EN1995-1-1: Eurocode 5: Design of Timber Structures. The GoFix® MS II screws come with a corrosion resistant patented SC 7® coating.

F-BohrFix® screws are also included for pinning of non-load-bearing components eg counter battens etc.

KompeFix®

Performance of the battening system and cladding is enhanced by using KompeFix® flexible ventilation strips – helping it look better and last longer.

KompeFix® works as a flexible spacer that offsets the cladding from the battens to improve ventilation, and eliminate the moisture-trapping wood-to-wood contact. KompeFix® also provides some room for timber movement, which occurs when cladding boards react to the changing relative humidity levels in the atmosphere and either shrink or swell in response.

Securo Firebreather™ cavity barriers

Securo Firebreather™ cavity barrier is a tested and certified fire resistance rated product. It consists of two components: a stainless-steel mesh and an intumescent strip.

Unlike other products on the market, the patented design of the Securo Firebreather™ is also highly effective under sudden or direct flame exposure, where situations like flashover or rapid flame growth are occurring. In these circumstances the mesh acts immediately to block the passage of flame and burning embers, while the heat activated intumescent strip expands and fully blocks the cavity.

Summary

- Independently assessed by an engineer – complies with EN 1995-1-1: Eurocode 5: Design of timber structures, and is suitable for fixing external timber cladding in the harshest UK conditions

- Rapid sustainable construction – easy to install, dismantle at end of life and reuse

- Enhanced longevity and performance – Thermopine® is highly durable and stable thanks to thermal treatment

- Environmentally friendly – does not contain hazardous chemicals, unlike standard preservative impregnated softwood battens

- Russwood can offer assistance with detailing and installation advice, and quantifying of the system requirements

Full technical information available on request. Please get in touch for assistance with detailing and installation advice, and quantifying of the system requirements.