Stopping the spread of fire in ventilated cavities: a guide to fire cavity barriers

External timber cladding should always be installed with a ventilated cavity behind it, in order to allow moisture dissipation and ensure adequate ventilation of the cladding façade. Cavities such as this can pose a fire risk without appropriate cavity fire stopping measures. To prevent the spread of fire and smoke, cavity barriers can be installed at key points. Over to Russwood’s Managing Director, John Russell to tell us more.

Fire Safety

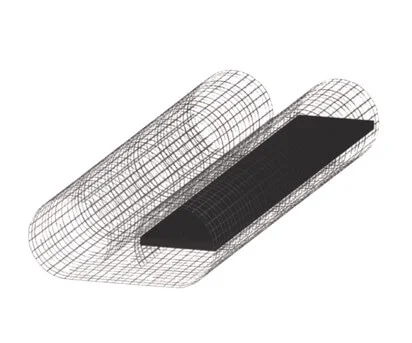

Ensuring appropriate fire safety measures are in place should be of the highest importance in any new building. Where open rainscreen cladding is used to form the outer envelope of a building, it will be fixed onto the substructure with a ventilated cavity in between. This cavity is essential to ensure the free flow of air, enabling the drying of timber and evaporation of moisture in the air, ensuring the longevity of the cladding. The cavity, however, does pose a fire risk. If a fire were to occur, flames could enter the cavity causing a ‘chimney effect’ which would allow the flames to spread. This risk can be mitigated with proper use of fire cavity barriers.

Cavity Barriers vs Fire Stops

It is important to note the differences between cavity barriers and fire stops. A fire stop, does what it says, but doesn’t allow ventilation, which is essential for a free flow of air and consequently a healthy building. Cavity barriers on the other hand, allow the building to breathe while simultaneously preventing the spread of fire through the cavity. In the event of a fire the heat activated intumescent strip expands, sealing off the cavity and containing the spread of flame behind the cladding. When and where fire cavity barriers should be installed is dependent on the use of the building. At a minimum there will be cavity barriers around the perimeter of the façade and at any window or door. You must check the Fire Safety Standards for your location – note they differ between England and Wales, and Scotland.

Securo Firebreather®

Securo Firebreather® Cavity Barriers take the concept of passive fire protection one step further, by the inclusion of the stainless-steel mesh component. The mesh acts to interrupt the flow of hot gases, arresting the flame, and preventing the passage of sparks and burning embers while the intumescent strip deploys to seal the cavity. Conventional intumescent strip cavity barriers take time to expand and seal the cavity – around 1-2 minutes – during which time flame and burning embers could bypass the cavity barrier before it has fully deployed. This poses a particular problem in flashover situations, where a fully developed fire may enter the cavity suddenly, and could spread quickly without immediate fire stopping capabilities. Securo Firebreather® represents a significant advancement in this area, offering immediate protection. Unlike other fire barriers, Securo also acts as an insect mesh. It is simple and efficient to install, with just two screws per piece. Russwood have developed an environmentally friendly, engineer assessed battening system which works in harmony with Securo Firebreather®.

Securo Firebreather Cavity Barriers

Learn more about Securo Firebreather

For more information about Securo Firebreather® Cavity Barriers, please get in touch with our team.